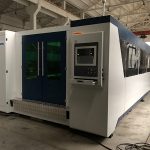

Описание на продукта

машина за лазерно рязане на влакна adopts the most advanced fiber lasers for industrial applications leader supplier RAYCUS / IPG new advanced fiber lasers. It represents the development trend of lasers which is widely used in various sheet and high-speed processing of non-ferrous metals.

Машина за лазерно рязане на фибри products, using fiber laser generator, the output of high-quality, high-density laser beam through an optical fiber transmission, the output of the laser, and then brought together by import optical focusing lens on the work piece surface, so that the area irradiated with a light spot on the work piece local instantaneous melting and gasification, controlled by a computer numerical control system moves the spot irradiated sites and automatic cutting.

SPECIFICATIONS FOR 3015 500-6000w машина за лазерно рязане на влакна | |||

Двигател | |||

мощност | 1000W | ||

Cutting area(L*W) | 3000мм * 1500мм | ||

Дебелина на рязане | 0.2mm-8mm | ||

Total electric power consumed | 10kw/h | ||

X axis route | 3050мм | ||

Y axis rout | 1525mm | ||

Z axis route | 120 милиметра | ||

X, Y Axis Orientation Precision | ± 0.03mm / m | ||

X/Y Axis Repeat Precision | ± 0.02 мм / m | ||

Weight of the Machine | 7000kg | ||

CNC система | Germany Beckhoff or customized | ||

лазер | RAYCUS/IPG Laser | ||

редуктор | Germany STOEBER | ||

Рейка и пиньон | Reddy Linden | ||

Linear Guides | Тайван HIWIN | ||

Охладителна система | Водно охлаждане | ||

Режеща глава | American lasermech | ||

Appliances | Франция Шнайдер | ||

servo motor | Matsushita | ||

Dimension(L*W*H) | 6000x2500x1800 | ||

Основните функции

1) Laser cutting is nowadays people mastered various cutting techniques best cutting method compared with conventional cutting

2) laser cutting advantages: thermal distortion, high cutting precision, low noise, no pollution, easy to implement automatic cutting

3) Although the initial investment large (inferior), but the processing cost than machining costs 50% less.

The main features of fiber lasers:

• fiber laser electro - high light conversion efficiency, conversion efficiency of over 25%, with little power fiber lasers without chillers, air-cooled, can greatly save power at work, savings in operating costs, to achieve maximum production efficiency;

• only run when required laser power, without generating additional gas laser, with the lowest operating and maintenance costs;

• fiber laser using semiconductor modular and redundant design, the resonant cavity without optical lenses, no start-up time, with adjustment-free, maintenance-free, high stability, it reduces the cost of parts and maintenance time, which is the traditional laser can not be compared;

• fiber laser output wavelength of 1.064 micron, 1/10, the output beam quality, high power density, highly conducive to the absorption of metallic materials, with excellent cutting and welding capability, so that the processing of the lowest CO2 wavelength;

• the whole optical fiber transmission route, and so no complex mirror light guide systems, the optical path is simple, stable structure, maintenance-free optical path;

• The cutting head contains a protective glass, so that the focusing mirrors and other consumables precious little consumption;

• optical fiber by exporting, to make the design of the mechanical system becomes very simple and very easy to integrate with robots or multi-table;

• After the laser shutter can be combined with a Multi machine, via optical fiber splitter, split into multiple simultaneously multiple, easy to expand functionality, easy to upgrade, easy;

• fiber lasers, small size, light weight, position of the movable, small footprint;

Metal cutting, electrical switch manufacturing, aerospace, food machinery, textile machinery, engineering machinery, locomotive manufacturing, agriculture and forestry machinery, elevator manufacturers, special vehicles, household appliances manufacturing, processing tools, IT manufacturing, oil machinery manufacturing, food machinery, diamond tools, welding, welding gear, metal surface treatment, decorative advertising, laser external processing services and other kinds of machinery manufacturing and processing industries.

Бързи подробности

Приложение: Лазерно рязане

Състояние: Ново

Тип лазер: Fiber лазер

Applicable Material: Metal, aluminum,stainless steel board,carbon steel

Дебелина на рязане: 0.2mm-8mm

Площ на рязане: 3000мм * 1500мм

Cutting Speed: According to the thickness

ЦПУ или не: Да

Режим на охлаждане: Водно охлаждане

Control Software: American Extrotec

Поддържан графичен формат: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Certification: CCC, CE, ISO, SGS, maquina de corte por laser

Следпродажбено обслужване: Инженери на разположение за обслужване на машини в чужбина

Power: 500-5000W

Machine structure: Dual drive

Total electric power consumed:10kw/h

X axis route: 3050mm

Y axis route: 1525mm

Z axis route: 120mm

Cutting head: American lasermech

servo motor: Matsushita

Rack and pinion: Reddy Linden

CNC system: Baichu or customized